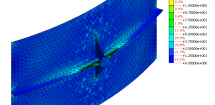

International design codes provide calculation methods to design equipment safely for static loads. However, for non-static loads, such as cyclic temperature and pressure changes, flow, and vibration, these calculation rules are insufficient to assess the required operating life of pressure vessels. The design codes refer to Finite Element Analysis (FEA) in such cases.

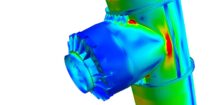

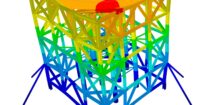

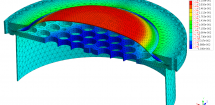

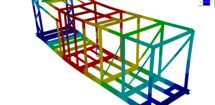

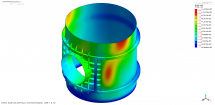

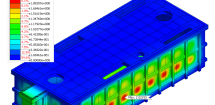

Hitard uses FEA and fatigue life analysis when local stresses need to be calculated in complex structures or equipment subjected to cyclic load cases, including pressure, temperature, and vibration. Through FEA, a model is developed to accurately define the structure and appropriate boundary conditions, such as displacements and forces.

The construction or equipment calculation model is prepared using adequate computer hardware and modern software tools.